text to clipboard

'Paint it (Vanta) black' - the world's blackest material is now in spray form

new applications include consumer products such as cameras, and luxury goods

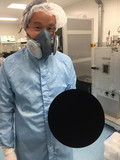

Newhaven, UK, March 10, 2016 --- A whole range of products can now take advantage of Vantablack’s astonishing characteristics, thanks to the development of a new spray version of the world's blackest coating material. The new substance, Vantablack S-VIS, is easily applied at large scale to virtually any surface, whilst still delivering the proven performance of Vantablack.

Vantablack's nano-structure absorbs virtually all incident light, enabling the performance of precision optical systems to be optimized. The material’s developer, UK-based Surrey NanoSystems, has mimicked the performance of its original Vantablack with a new version that can be sprayed onto objects, rather than deposited using a chemical vapour deposition (CVD) process.

Vantablack S-VIS greatly widens the potential applications space, making it possible to coat larger complex shapes and structures. It is applied at temperatures that are easily withstood by common plastics, further extending its use. Even though the material is applied using a simple spraying process, it traps a massive 99.8% of incident light. This property gives Vantablack S-VIS its ability to make objects appear to be two-dimensional black holes, as it becomes impossible to make out surface topography.

The only other commercially-available material that is darker than the new S-VIS version is original Vantablack, which set a world record for absorption of light at a staggering 99.965%. Vantablack was originally developed for satellite-borne earth observation imaging and calibration systems, where it increases instrument sensitivity by improving absorption of stray ultraviolet, visible and infrared light. Since then, many other applications have emerged, including solar-energy collector elements, functional surfaces in buildings and architecture, cinematographic projectors, high-performance baffles and lenses, and scientific instruments. Its ability to deceive the eye also opens up a range of design possibilities to enhance styling and appearance in luxury goods and jewellery.

"The original Vantablack coating has had a big impact on the market, and is helping many companies to bring out higher-performing equipment," says Ben Jensen of Surrey NanoSystems. "We are continuing to develop the technology, and the new sprayable version really does open up the possibility of applying super-black coatings in many more types of airborne or terrestrial applications. Possibilities include commercial products such as cameras, equipment requiring improved performance in a smaller form factor, as well as differentiating the look of products by means of the coating's unique aesthetic appearance. It's a major step forward compared with today's commercial absorber coatings."

Vantablack S-VIS is so effective that its performance far outstrips that of any other conventionally-applied coating, typically achieving a reflectance of less than 0.2%. Unlike other black absorbers, it offers this exceptional performance across a wide-range of viewing angles and wavelengths, which is critical for optical instruments, as well as in many aesthetic applications. It is, for example, some 17 times less reflective than the super-black paint used for minimizing stray light in the Hubble space telescope.

The active element of Vantablack S-VIS is a carbon nanotube matrix. The coating is applied using a proprietary process that includes a number of pre- and post-application steps to achieve its ultra-low reflectance.

Vantablack S-VIS can be applied to most stable surfaces, with the only major constraint being the ability to withstand temperatures of 100 degrees Centigrade, making Vantablack S-VIS suitable for many types of engineering-grade polymers and composite materials. The process is scalable and suitable for high-volume production on a range of substrate sizes.

The structured surface of Vantablack S-VIS means that it is not recommended for applications where it is subject to physical contact or abrasion. Ideally, it should be applied to surfaces that are protected, either within a packaged product, or behind a glass or other protective layer.

Coating with Vantablack S-VIS is offered as a service from Surrey NanoSystems’ processing centre in the UK. It is also available under license to companies wishing to integrate the coating into their production processes.

ENDS

For more information please contact:

Surrey NanoSystems, Euro Business Park, Building 24, Newhaven, BN9 0DQ, UK. t: +44 (0)1273 515899; enquiries@surreynanosystems.com; http://www.surreynanosystems.com

Media contact: Ben Jensen, t: +44 (0) 1273 515899

BACKGROUND INFORMATION

A few of Vantablack S-VIS's technical specifications:

* THR (total hemispherical reflectance) 0.2% at 700 nm and 0.17% at 1064nm (near-infrared spectrum)

* Performs across a wide spectrum from ultraviolet (UV) to near infrared (NIR)

* Shock and vibration resistance to MIL-810G

* Thermal shock and cycling from -196 to +200 degrees C

* Super-hydrophobic

* High performance at extreme viewing angles (TIS - 0.6% at 70° VIS)

About Surrey NanoSystems

Surrey NanoSystems combines the best of British ingenuity and materials science for use in the development, growth and commercialization of strategically important nanomaterials, and particularly in the development and commercialization of super-black coatings. The company was founded in 2006 as a spinout from the University of Surrey, and is backed by some of the UK’s most successful IP commercialization and venture capital providers including IP Group PLC, Octopus, NewWave Ventures and Parkwalk Advisors. Located near Brighton in the UK, the company operates a modern cleanroom based nanomaterials research and production facility. www.surreynanosystems.com

|

|